The Museum

Shut your mout.

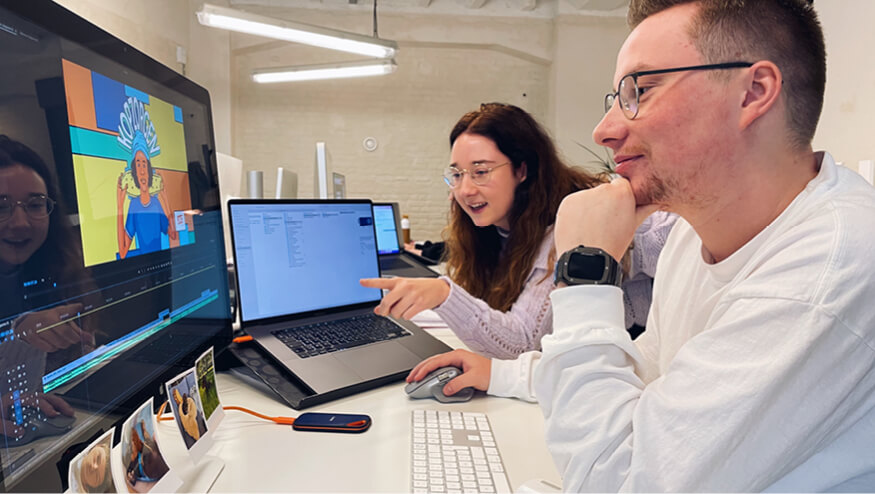

The Stay Wild headquarters include a unique museum. Our museum contains some unique pieces of the past of the malt house and serves as a creative playground and outlet for Stay Wild. The museum is a place where a piece of industrial heritage is being stored with a lot of pride, in addition it acts as an exhibition room and creative hotspot. In here, creativity and industrial heritage go hand-in-hand.